Cheaper, Efficient solution for Discrete Manufacturing industry.

Right from buying your raw materials to finishing the product, Effitrac stands by you.

Get StartedFeatures

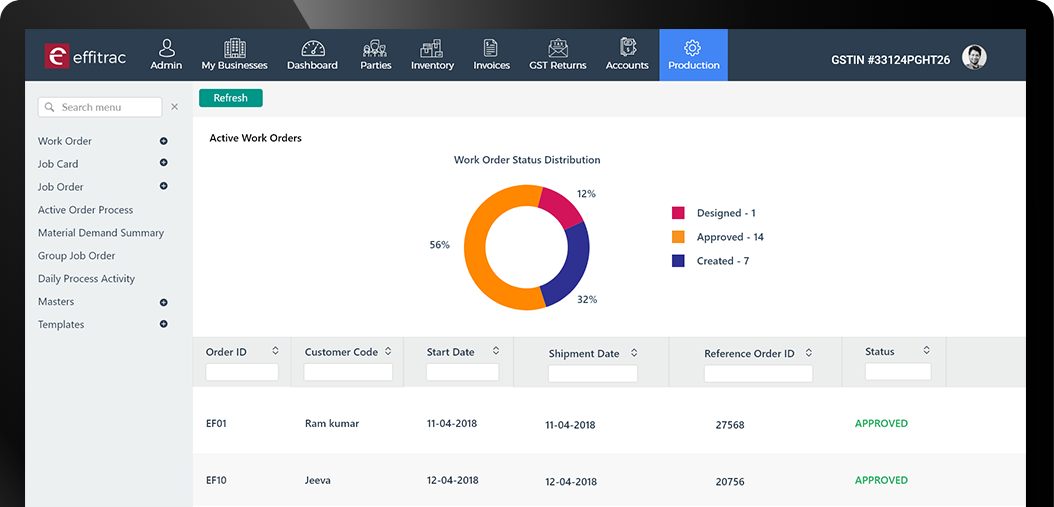

Work order

Create, view and search for work order automatically to track maintenance and repair work and generate a WO status report of it.

Material Demand Summary

Summarise your material demand based on your job order, customer, manufacture materials by providing the product category and product class.

Daily process activity

In discrete manufacturing, check the day-to-day activities that are carried out based on different manufacturing styles.

Job order maintenance

Initiate, view, search and create job orders which you have outsourced to other vendors. Notify any issues, generate receipts and inspect it using Effitrac.

Active Order Process

Process your active orders by providing the order ID, style ID and get to know the status and complete details via simple dashboard.

Process Activity detail

Check the processes that has taken place for assembling your product from the start date to end date based on production unit, type, employee code and vendor.

Production Operation

Create, view and search for production details and generate status report & view the process activity details.

Bill of Materials

Based on production order planning, UOM and material processing, generate Bill of Materials for raw materials.

Pre budget and costing

Prepare a budget in advance and note down the costing details.

Search TNA plan

Search for a Time and Action plan based on planned & actual start and end date.

Benefits

Analyse better

With graphical view and impeccable dashboards, you can analyse your manufacturing processes in a better way.

Reduce the expenses

Managing manufacturing expenses is tougher. Now easily manage it and keep your expenses in control.

Increase production efficiency

Try out various manufacturing approaches, track it in real-time and increase your efficiency in turn.

Enhance customer service

With end-to-end communication with customers through CRM, you can carry out your manufacturing activities without hassles.

Monitor the Quality of raw materials

Quality management is a must for your raw materials. You can easily monitor the quality through Effitrac.

Easy Integration with other platforms

You can integrate your manufacturing ERP with any other platform like HRMS & Payroll, CRM, Billing & Accounting for better results.